A partnership between two Albertan companies will provide 3D printers with engineering-grade filaments made with captured carbon.

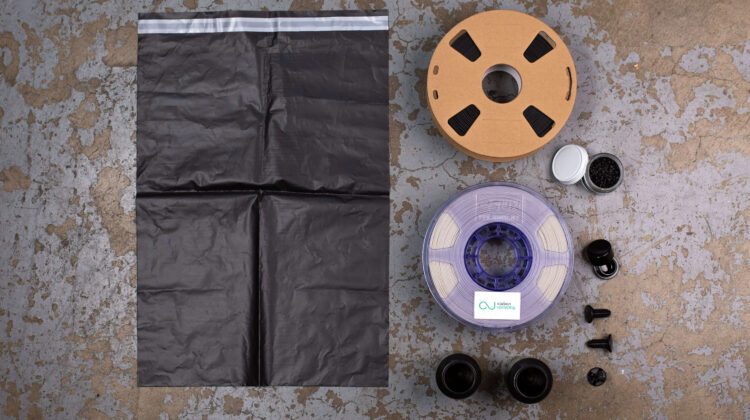

Oco, a Carbon Upcycling company, and Canadian Filaments have partnered to distribute first-of-their-kind PLA and PETG filaments. The filaments to be sold under the “CUT” product name were developed for printers looking for a more sustainable material option.

As the effects of current industry practices on the climate become more apparent, printers are now searching for methods to reduce the environmental impact of their products.

Oco and Canadian Filaments designed CUT filaments to meet this growing demand for sustainable materials by leveraging CO2 emissions and recycled graphite processed through Oco’s carbon capture and utilization technology. The resulting CUT PLA and PETG demonstrate exceptional strength and resiliency, qualities unique to the products’ composition.

As part of empowering printers in their transition to sustainable materials, Oco and Canadian filaments will also be piloting a take-back and recycling program. The joint circular initiative aims to limit waste across the filaments lifecycle by transforming the printed material back into engineering-grade filament.

“We are proud to partner with Oco to provide our clients with this exciting new filament. The collaboration between Canadian Filaments and Oco is an example of the advancements in technology and sustainability being made here in Alberta,” said Alex Neumeyer, CEO of Canadian Filaments.

The first company to deploy PETG in a commercial application will be fellow Alberta-based CleanO2 Carbon Capture Technologies. The filament will be used to 3D print components of CleanO2’s small-scale carbon capture device, CarbinX, which transforms CO2 into an ingredient used in products ranging from soaps to fertilizers and glass.

“We’re impressed by CUT PETG. It extrudes cleanly, and we are able to get consistently high resolution. In fact, we use it to produce finished components for our CarbinX units,” said Jaeson Cardiff, CEO of CleanO2. “In some ways, it’s the ultimate circular economy story. We’re using captured carbon to produce carbon capture devices.”

“Consumer buying has the power to change our collective impact on the environment, and we’re demonstrating this potential locally, right here in Alberta. We’re proud to partner with Canadian Filaments to provide printers with this new line of sustainable circular materials,” said Peter Zhou, Technical Lead at Oco.

The CUT PLA and PETG filament will be available for purchase at canadianfilaments.ca

Leave a Reply