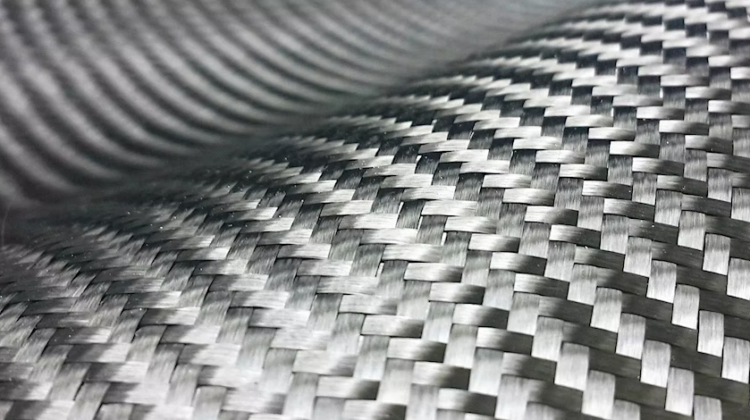

Regarded as a strategic material in next-generation structure and design, carbon fibre can be significantly stronger than metals such as aluminum and steel, while also offering thermal and conductivity advantages.

However, currently most carbon fibre production is neither cost-efficient nor energy-efficient.

Last year, we wrote about an Edmonton-based company working toward its vision of unlocking the productive efficiency of carbon fibre.

Cumulating from several years of innovation, Thread Innovations has developed patent-pending technology to produce carbon fibre from Alberta oil sands bitumen-based feedstocks.

Government and startups alike are innovating the space to disrupt the global carbon fibre production and supply chain with sustainable impact.

This includes the Province of Alberta, which is motivated to utilize regional bitumen supplies to advance eco-friendly carbon fibre creation in Canada.

This desire is represented by the region’s Carbon Fibre Grand Challenge, which saw Alberta Innovates and Emissions Reduction Alberta in 2023 fund projects across Western Canada.

Among 13 applicants, Thread received $1M from Alberta Innovates and $3M from ERA for a total of $4M in funding as chief technology officer Dr. Weixing Chen and his team look at proprietary ways to convert bitumen into high-value carbon fibre by using vacuum refinery residue-derived and asphaltenes-based precursors.

The challenge is a marathon not a sprint, slated to complete in 2026.

In 2024, the challenge enters its final, longest, and most critical phase. By the end of this stage, each recipient’s technology will be “at a point where a company could make a funding decision” for a commercial project, according to Byran Helfenbaum, associate vice-president of clean energy for Alberta Innovates.

“It’s really to get it out of the lab and start hitting the key specifications, identifying the existing and new markets, and pumping out prototypes that can be tested,” he informed Canadian Energy Centre.

Thread Innovations is already building a new facility to produce samples for potential buyers, according to Weixing Chen. The facility will also demonstrate his company’s ability to scale up production.

“Our target is to complete the current project and then establish a commercialization plan in 2025,” Chen told CEC.

The CTO is focused on improving characteristics of the carbon fibre produced through Thread’s technology with an aim to build up commercial demand.

“This is a great opportunity for me to challenge myself moving forward to develop this technology that will benefit society,” he said.

Leave a Reply